How to Prepare Bar Bending Schedule of Slab with Example: A Comprehensive Guide

If you’re looking to build a structure that is reinforced with concrete, you’ll need to prepare a bar bending schedule for the slab. A bar bending schedule is a document that details the reinforcement steel required for the construction of the slab. It is a critical component of any construction project that involves concrete. This article will explore how to prepare a bar bending schedule for a slab with an example. We’ll cover everything from the basics to the advanced techniques. So, let’s dive right in.

Understanding Bar Bending Schedule (BBS)

A bar bending schedule is a document that provides information about the quantity, shape, and size of reinforcement steel required for a structure. It is also known as a reinforcement schedule or rebar schedule. The BBS aims to ensure that the reinforcement steel is used efficiently and effectively to provide the required strength to the structure.

To prepare a bar bending schedule, you’ll need a set of structural drawings showing the details of the required reinforcement steel. These drawings will indicate the placement of bars and their sizes. You can prepare a bar bending schedule for the slab using these drawings.

Preparing the Bar Bending Schedule

Step 1: Determine the Total Weight of Reinforcement Steel Required

The first step in preparing the bar bending schedule is determining the total weight of the reinforcement steel required. This can be calculated using the following formula:

Total Weight of Reinforcement Steel = Length of Bar x Number of Bars x Unit Weight of Bar

For example, if the length of the bar is 10 meters, and you require 20 bars, and the unit weight of the bar is 0.617 kg/m, then the total weight of the reinforcement steel needed will be:

Total Weight of Reinforcement Steel = 10 x 20 x 0.617 = 123.4 kg

Step 2: Calculate the Cutting Length of the Bars

The next step is to calculate the cutting length of the bars. The cutting length is the bar required to bend and shape it as per the drawing. You can calculate the cutting length using the following formula:

Cutting Length of Bar = Development Length + Bend Length + Extra Length

The development length is the length of the bar required to develop its full strength, the bend length is the length needed to make bends, and the extra length is the additional length necessary for laps, hooks, or anchoring.

Step 3: Prepare the Bar Bending Schedule

Once you have determined the total weight of reinforcement steel required and the cutting length of the bars, you can prepare the bar bending schedule. The bar bending schedule should include the following details:

- Bar mark number

- Length of the bar

- Cutting length of the bar

- Shape and size of the bar

- Total weight of the bar

- Number of bars required

- Make sure to organize the bar bending schedule in a logical and easy-to-read format.

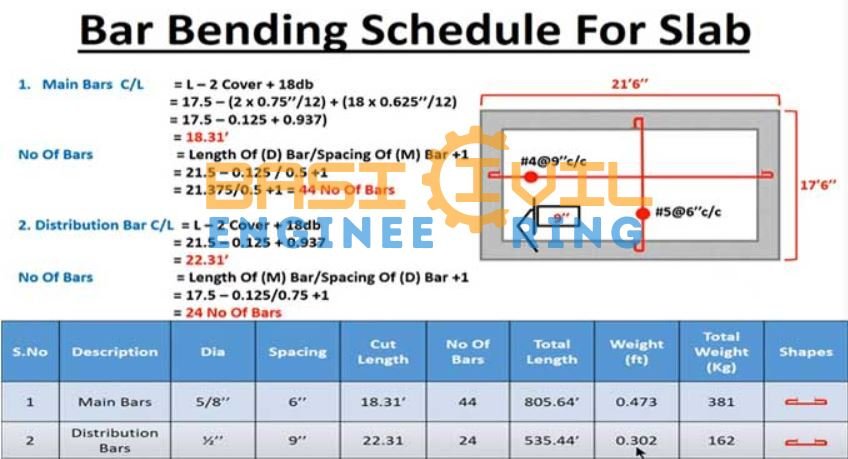

Example of a Bar Bending Schedule for a Slab

Let’s look at an example of a bar bending schedule for a slab. We’ll likely need to prepare a bar bending schedule for a slab that is 5 meters by 5 meters and has a thickness of 150 mm. The drawing indicates that we need to use 12 mm bars at a spacing of 150 mm in both directions.

Step 1: Determine the Total Weight of Reinforcement Steel Required

As per the drawing, the number of 12 mm bars required at a spacing of 150 mm in both directions will be:

Number of Bars = ((Length of Slab/Spacing)+1) x ((Width of Slab/Spacing)+1) x Number of Layers

Number of Layers = Thickness of Slab/Bar Diameter

Number of Bars = ((5/0.15)+1) x ((5/0.15)+1) x (150/12) = 1000

Using the unit weight of 12 mm bar as 0.888 kg/m, the total weight of reinforcement steel required will be:

Total Weight of Reinforcement Steel = Length of Bar x Number of Bars x Unit Weight of Bar

Total Weight of Reinforcement Steel = 5 x 5 x 1000 x 0.888 = 22,200 kg

Step 2: Calculate the Cutting Length of the Bars

To calculate the cutting length of the bars, we’ll use the formula mentioned earlier:

Cutting Length of Bar = Development Length + Bend Length + Extra Length

Development length, bend length, and extra length will depend on the type of reinforcement detailing used. For this example, we’ll assume a standard reinforcement detailing with 45-degree bent-up bars at the edges.

The development length of a 12 mm bar is 42 times its diameter, which is 12 x 42 = 504 mm. The bend length is 10 times the diameter, which is 120 mm. The extra length required for anchorage will be 300 mm.

Cutting Length of Bar = 504 + 120 + 300 = 924 mm

Step 3: Prepare the Bar Bending Schedule

Finally, we can prepare the bar bending schedule for the slab using the details calculated in the previous steps. The bar bending schedule for the first layer of reinforcement will look like this:

Bar Mark Length (m) Cutting Length (mm) Shape and Size Total Weight (kg) Number of Bars

B1 5 924 12 mm 888 80

B1 5 924 12 mm 888 80

B1 5 924 12 mm 888 80

B1 5 924 12 mm 888 80

B1 5 924 12 mm 888 80

B1 5 924 12 mm 888 80

B1 5 924 12 mm 888 80

B1 5 924 12 mm 888 80

B1 5 924 12 mm 888 80

Note: The total weight of the bar is calculated by multiplying the weight per meter (0.888 kg/m) by the length of the bar (5 meters) and the number of bars required (80).

Conclusion:

Preparing a bar bending schedule for a slab requires attention to detail and an understanding of the reinforcement detailing used. By following the steps mentioned above and using the appropriate formulas

Read More

-

TYPES OF BUILDING FOUNDATIONS, SELECTION CRITERIA, AND BASIC REQUIREMENTS

-

How to the Plan for Cold Weather Masonry Construction?

-

Construction projects using concrete: Materials, Types, and Applications

-

Differents Types of Beams in Construction

-

What is the Bricks & Important Tests on Brick

-

Technology for the locating underground utilities

-

Curing of the Concrete | Curing time And Duration | What is Curing methods

-

Tendering Procedures and Methods in Construction

-

Types Of Vibrators Used In the Construction

-

Railway / Why Crushed Stones Are Used In the Railway Track

-

How to Calculate Cutting Length of Stirrups in columns

FAQs

What is a bar bending schedule?

A bar bending schedule is a document that provides information about the quantity, shape, and size of reinforcement steel required for a structure. It ensures that the reinforcement steel is used efficiently and effectively to strengthen the structure.

Why is a bar bending schedule important?

A bar bending schedule is essential because it ensures that the reinforcement steel is placed in the correct position and at the right length to provide the required strength to the structure. It also helps to minimize wastage and reduces the cost of construction.

What steps are involved in preparing a bar bending schedule for a slab?

The steps involved in preparing a bar bending schedule for a slab are:

Determine the total weight of reinforcement steel required

Calculate the cutting length of the bars

Prepare the bar bending schedule

What information is included in a bar bending schedule for a slab?

A bar bending schedule for a slab should include the following details:

- Bar mark number

- Length of the bar

- Cutting length of the bar

- Shape and size of the bar

- Total weight of the bar

- Number of bars required

How can I ensure that my bar bending schedule is accurate?

To ensure that your bar bending schedule is accurate, you should use the structural drawings provided by the engineer or architect, follow the design specifications, and double-check your calculations. Having someone else review your bar bending schedule for accuracy is also a good idea.