How to the Plan for Cold Weather Masonry Construction?

How to the Plan for Cold Weather Masonry Construction?

Cold-weather masonry construction demands several precautions to be taken by the builders. To avoid seasonal delays associated with cold weather construction, the builders or contractors employ dynamic procedures, equipment, mason contractors, supplies, etc.

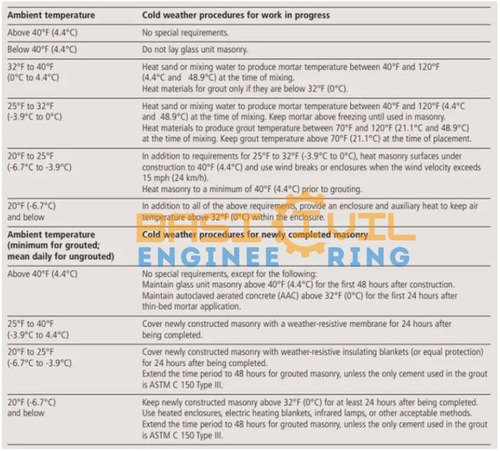

The “Specification for Masonry Structures” of ACI 530.1-08/ASCE 6-08/TMS 602-08 specifies the minimum cold weather masonry construction requirements. Masonry construction must be carefully planned in areas where the temperature is less than 44oF (4.4oC). Cold weather alters the properties and behavior of masonry mortar, eventually leading to cracking and other problems. As a result, masonry construction in cold weather necessitates special precautions to keep the mortar warm and workable.

This article discusses the effects of cold weather on mortar and masonry construction tips for cold weather.

Effect of Cold Weather on Masonry Mortar

The low temperature of the surrounding environment lowers the temperature of the mortar below average, resulting in the following effects:

- When the temperature of the mortar falls below average, the water freezes and causes a volume change, causing the cannon to expand. As a result, the amount of water required to achieve a given consistency decreases.

- Lower temperatures slow the hydration process and reduce the strength gain of the mortar mix.

- The mortar’s initial and final setting times are significantly delayed.

- The freezing of water in the mortar is just enough to cause cracks. Ice on the surface of masonry units weakens the bond between the mortar and brick units.

- The rate of strength gain of mortar is slowed during cold temperatures.

Tips to Work with Masonry and Mortar in Cold Weather

The following are general guidelines to follow when performing masonry construction in cold weather:

1. The cold weather performance of masonry materials must be optimized.

2. Keeping raw materials safe from ice and cold weather.

3. Apply the material and mortar while it is hot.

4. Insulating the structures while they cure (Figure-2).

5. Defending or enclosing work areas (Figure-3).

6. Keep the site’s workers safe (Figure-4).

Workers appear to be less productive in cold weather. According to a field observation conducted by the Portland Cement Association, workers working within a protected area were found to work until 12°F to 2°F (PCA). A better working environment for mixer operators can significantly increase their productivity.

Storing and Handling Materials for Masonry Construction in Cold Weather

- All masonry construction materials must be protected from rain and snow. The materials can be placed on planks and covered with tarps.

- Always choose dry mortar ingredients that are delivered in bulk.

- The delivered fine aggregates may contain frozen lumps. These can be heated and crushed to make sand.

- The masonry units must be installed over unfrozen ground. The surface temperature must not be less than 20°F. It must be clear of ice and snow.

- Before construction, always heat the masonry materials. This promotes cement hydration.

- The mortar should be placed on heated surfaces such as metals to avoid freezing.

- During cold weather, glass masonry units should not be installed.

Relateds Posts

-

How to plan the budget for home renovation

-

TYPES OF BUILDING FOUNDATIONS, SELECTION CRITERIA, AND BASIC REQUIREMENTS

-

How to the Plan for Cold Weather Masonry Construction?

Mixing Mortar for Cold Weather Masonry

- Mix the mortar in small batches. It would prevent the materials from absorbing water. As a result, frosting is restricted.

- Heating and maintaining temperature are used to place the mortar. Due to external warming, do not allow the mortar to dry out too quickly.

- The mortar sand or water can be heated and mixed. It would assist in keeping the mortar temperature below 40°F.

- If hot water is used, it must first be mixed with cold sand before being mixed with cement. This is done to prevent the cement from flash setting.

- By using high-early cement, the rate of hydration can be increased. To accomplish this, an accelerator or admixture can be used. Accelerators are used to speed up the development of early-age strength. As a result, they do not allow the mortar to freeze for a shorter period of time to facilitate early strength gain. ASTM C1384 contains information on the accelerators and admixtures used in masonry mortar.

- Admixtures cannot be used unless specified in the project details, according to ASTM C 270. Another method for increasing the reaction rates of mortar in cold temperatures is to use fineness cement such as ASTM C 150 Type III.

- The masonry must be installed on a stable, unfrozen foundation. Never place it on a snow-covered or ice-covered surface. Snow weakens the connection between the masonry unit and the foundation. When the snow melts, the masonry may move.

Protecting New Masonry Structures from Cold Weather

- Cover the walls with plastic once the masonry construction is completed. When temperatures are below 32°F, plastic prevents water from entering the masonry.

- Heat loss can occur at temperatures ranging from 32°F to 20°F. This can be avoided by wrapping the wall in insulation blankets.

- When the outside temperature is between 20°F and 0°F, the walls must be kept at around 40°F. It can be done with a 1-inch insulation blanket. Heating can be applied to both sides of the masonry wall.

- Windbreakers can be installed if the area’s wind speed exceeds 15 miles per hour.

The primary goal of a cold-weather construction plan is to reduce and eliminate the harmful effects of cold weather on masonry materials, construction, and workforce in an economical manner. The mason contractor must assess the efficacy and practicability of the techniques used for the specific project and weather conditions.

Frequently Asked Questions

What are the specifications for cold-weather masonry construction?

The “Specification for Masonry Structures” of ACI 530.1-08/ASCE 6-08/TMS 602-08 specifies the minimum cold weather masonry construction requirements. Masonry construction must be carefully planned in areas where the temperature is less than 44 degrees Fahrenheit (4.4 degrees Celsius). Cold weather causes changes in the properties and behavior of masonry mortar. The following are the general requirements for cold-weather masonry construction:

1. The choice of materials for cold-weather performance must be optimized.

2. Keeping raw materials safe from ice and cold weather.

3. Apply the material and mortar while it is hot.

4. Insulating the structures while they cure.

5. Defending or enclosing work areas.

6. Keep the site’s workers safe.

Can masonry units be used in masonry construction in cold weather?

During cold weather masonry construction, dried masonry units must be used. Wet and frozen masonry units weaken the bond between the masonry units and the mortar. This would eventually impact the quality and strength of the wall assembly.

What exactly is a cold-weather construction strategy?

The primary goal of a cold-weather construction plan is to reduce and eliminate the harmful effects of cold weather on masonry materials, construction, and workforce in an economical manner. The mason contractor must assess the efficacy and practicability of the techniques used about the specific project and weather conditions.