Differents types of beams in construction

What is Beam?

Beam is a type of structural member whose cross section is much smaller than its length and which is subject to lateral load.

In other words, a beam is a horizontal bar that is bent by a side load or couple. A beam is also a horizontal bar that is bent by bending stress.

Different beams, like fixed beams, cantilever beams, etc., are used in different situations based on their needs.

Types of Beams in Constructions

There are different kinds of beams that are categorized by the following:

- Based on Conditions for Support

- Depending on the materials used to build

- Based on shapes cut in half

- Using Geometry

- Based on the condition of equilibrium

- Depending on how it was built

- Others

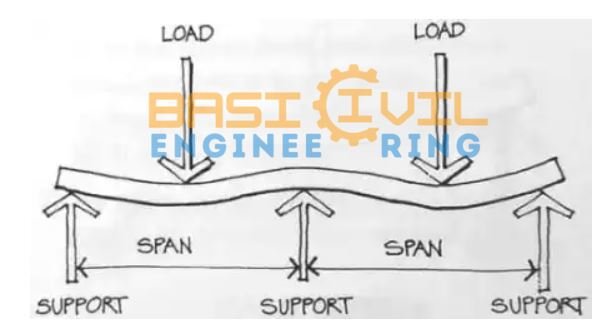

1. Continuous Beam

A continuous beam has more than two supports distributed along its entire length.

2. Cantilever Beam

If a beam is the fixed at one end and set to be free at the other end, it is termed as a cantilever beam. The beam distributes the load back to the support, where it is forced against a moment and shear stress. Cantilever beams allow the creation of a bay windows, balconies, and some bridges

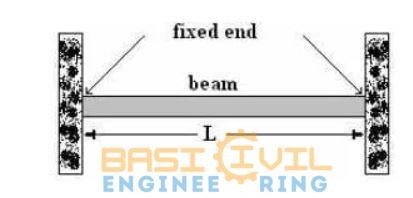

3. Fixed Beam

It is held up at both ends and can’t turn because it is fixed. A built-in beam is another name for it. The reactions don’t happen at the same time as the fixed ends.

4. Simply Supported Beam

It is one of the most basic building parts, with two ends that rest on supports but are free to turn. At one end, it has a pin support at the other, it has a roller support. Depending on the load, it has to deal with shearing and bending.

Based on Construction Materials

5. Reinforced Concrete Beams

It is made of concrete and steel reinforcements. Sometimes a reinforced concrete beam is hidden in a reinforced concrete slab. This is called a “hidden beam” or “concealed beam.”

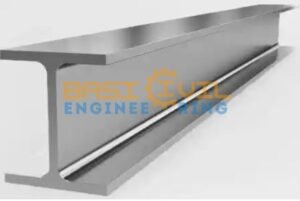

6. Steel Beams

It is made of steels and is used for many different things.

7. Timber beams

The timber beam is made of wood and was employed in the past. However, the use of such a beam in construction sector has significantly decreased in recent years.

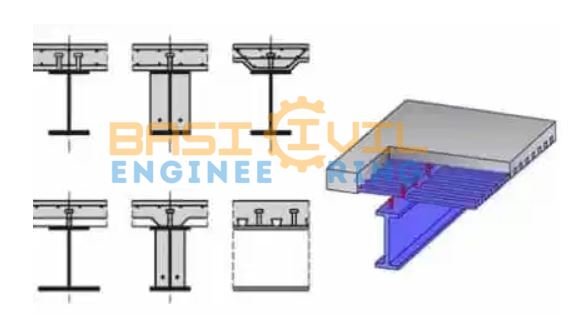

8. Composite Beams

Steel and concrete for example, are two examples of multiple types of the materials that go into the construction of the composite beams. depicts various valid cross-sections for the composite beam.

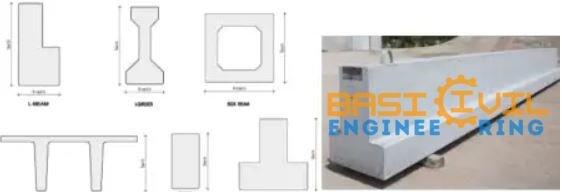

Based on Cross-Section Shapes

For use in various parts of structures, beams come in a variety of cross-sectional shapes. These beams can be made of composite materials, steel, or reinforced concrete:

Based on Method of Construction

Read More

-

How to Calculate Cutting Length of Stirrups in columns

-

Top 30 Questions and Answers for Interviews About Surveying

-

Railway / Why Crushed Stones Are Used In the Railway Track

-

Construction projects using concrete: Materials, Types, and Applications

-

Differents Types of Beams in Construction

-

16 Different Types Of Heavy Machinery Used In The Constructions

-

TYPES OF BUILDING FOUNDATIONS, SELECTION CRITERIA, AND BASIC REQUIREMENTS

-

What is the Bricks & Important Tests on Brick

-

Types of the Roads or Classification of Roads

-

Difference between a one-way slab and a two-way slab

9. Deep Beam

According to ACI Code, a deep beam has a clear span to depth ratio of less than four and a significant depth. A compression force created by the combination of the load and the reaction transfers a sizable load to the supports. As a result, unlike with conventional beams, the strain distribution is no longer regarded as linear.

10. Prestressed Concrete Beam

Construction of the pre-stressed concrete beam involves stressing strands before placing loads on it. Pre-stressed concrete beams come in two different varieties pre-tensioned and post-tensioned.

11. Precast Concrete Beam

Manufacturing facilities produce this kind of beam. Therefore, compared to on-site construction, the construction environment is more manageable. As a result, the beam’s concrete would be of higher quality.

It is possible to manufacture a variety of cross-sectional shapes, including T-, Double-, and Inverted T-beams.

12. Cast In-situ Concrete Beam

This kind of beam is built on the project’s site. So, after first fixing the forms, new concrete is poured and given time to harden. Loads would then be imposed.

Reinforced concrete cross sectional shapes include:

13. T-section beam

The majority of this type of beam is built monolithically from a slab of reinforced concrete. It is occasionally necessary to construct an isolated T-beam to improve the concrete’s capacity to withstand compression.

Additionally, inverted T beams can be built in accordance with the constraints placed on loading.

14. Rectangular beam

Buildings and other structures made of reinforced concrete frequently use this kind of beam.

15. L-section beam

This kind of beam is built monolithically with a slab of reinforced concrete around the outside of the building.

Among the steel cross-sectional shapes are:

Steel beam cross sections come in a variety of shapes. Each cross-sectional shape offers more benefits than other shapes in a particular situation.

Steel beams can have cross-sections in a variety of shapes, including square, rectangular, circular, I, T, H, C, and tubular.

Based on Geometry

16. Straight beam

The majority of beams in structures have a straight profile and are known as straight beams

17. Curved beam

Curved-profile beam, as in the case of circular structures.

18. Tapered beam

A tapered cross-sectional beam.

19. Statically Determinate Beam

The only way to solve reactions for a statically determined beam is by using equilibrium conditions. Equal to the number of equations is the number of unidentified reactions.

20. Statically indeterminate beam

Equilibrium conditions alone are insufficient for a statically indeterminate beam to solve reactions. Therefore, compared to beams that are statically determinate, the analysis of this kind of beam is more difficult.

21. Girder

Beams that support heavy loads typically use steel sections.

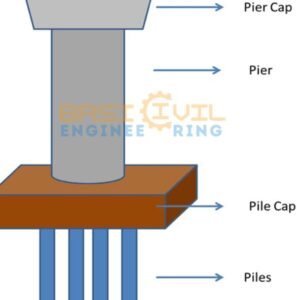

Types of pier and beam foundations

These are the kinds of piers we’ve seen in our area of Central Texas. There may be a few more that aren’t on the list. We will list them from simplest to most modern/reinforced materials used in pier and beam home foundations. In this way:

- Masonry piers

- concrete piers

- Drilled caissons or piers

- Timber piers

Masonry Piers

Masonry piers are one of the most common types of building foundations for both homes and businesses. They are very strong and, with the right care, can last for many years. They are usually made of concrete, brick, or stone, and steel rods or rebar are often used to make them stronger.

Most buildings in areas with strong soil use masonry piers. They are also often used in places where the ground isn’t flat or where the water table is high. They can be built on any kind of soil, but sandy or clay soils are most often used.

Concrete Piers

A concrete pier foundation is a type of foundation that supports a building with concrete piers. Most of the time, the piers are placed under the structure at regular intervals and are often used with other types of foundations, like footing foundations.

Pier footings made of concrete are very strong and can hold a lot of weight. They can also stand up to fire and bugs. They don’t need much care, and if you take good care of them, they can last for many years.

Timber Piers

Timber piers are another common type of building foundation for both homes and businesses. They are made from wood that has been treated with pressure and usually have steel rods or rebar in them to make them stronger.

Most of the time, timber piers are used in areas with strong soil. They are also often used in places where the ground isn’t flat or where the water table is high. Timber piers can be built on any type of soil, but they are most often used on sandy or clay soils.

Drilled Caissons or Piers

Most of the time, drilled caissons refer to the round foundation. A drilled caisson is mostly a compressed member that has an axial load at the top and a reaction at the bottom. Drilled caissons come in three different kinds:

- Caisson made of concrete with a bigger bottom

- Caisson made of steel pipes filled with concrete

- Caissons with a steel core and a concrete shell inside the steel pipe

Types of wood beams

Large wood pieces called beams can support heavy loads. Both solid wood and engineered wood are acceptable materials for them.

There are numerous available varieties, each with unique qualities:

Solid wood beams

A single piece of wood makes up a solid wood beam. They are extremely sturdy, as their name suggests. They have been employed for centuries to create a variety of buildings and structures.

These beams have an undeniable charm due to their rugged appearance, but they can be quite expensive. They may be more challenging to install due to their significant weight.

Laminated veneer lumber (LVL) beams

Engineered wood includes LVL or laminated veneer lumber. They consist of several 3 mm thick wood veneers that have been heated and pressed together under intense pressure to form a straight line.

Compared to solid wood beams, these structural composite lumber beams are much less likely to warp, twist, bow or shrink. To increase strength and durability, some veneers can even be positioned with the wood grain perpendicular to the surrounding material.

Glued laminated timber (glulam) beams

Glued laminated timber (glulam) beams are constructed of wood slats that range in thickness from 6 mm to 45 mm, are glued together using a water-repellent adhesive, and have all of their fibres oriented in the same direction. Their mechanical toughness, dimensional stability, and aesthetic attributes make them highly prized.

The construction of large wooden-framed buildings benefits from the impressive length that these engineered wood beams can reach.

Glued solid timber beams

The thickness of the wood is the primary distinction between glued solid and glued laminated timber beams. Glued solid timber planks are thicker than 45 mm, whereas glued laminated timber slats are less thick.

Compared to conventional solid wood beams, these beams are more durable and have better mechanical properties. Both the construction of timber frame homes and the exposure of exposed timber frames use them.

Prefabricated I-beams

Custom-made prefabricated I-beams are structural and load-bearing products. The “I” configuration consists of a vertical portion (the web) between the flanges and an upper and lower horizontal component (the flange).

The web is typically made of oriented strand board (OSB), while the flanges are typically made of laminated veneer or laminated wood.

These prefabricated I-beams have the advantage that, despite their length, they can be handled on construction sites without the use of pricey handling machinery because of their light weight. The “I” configuration produces high rigidity and flexural strength.

FAQ’s

What are beams in building?

Beams are horizontal pieces of a building’s structure that can handle vertical loads, shear forces, and bending moments. They move loads that are put on them along their length to the walls, columns, foundations, etc. at their ends.

What are RCC beams or cast-in-place beams?

The RCC beams are made of concrete and bars that hold the concrete together. They can handle vertical loads, forces that pull them apart, and bending moments.

What is a beam that doesn’t stop?

Along its whole length, a continuous beam has more than two supports.

What are the different types of support conditions in beams?

- Roller

- Pinned

- Fixed

What are the different types of beams based on how they are held up?

1. Just held up a beam

2. Static beam

3. The cantilever beam

4. Beam that stays on

What are beams and its types?

In engineering, there are many different kinds of beams. Simply supported: A beam that is held up by its ends and can spin freely and doesn’t have any moment resistance. A beam that is supported on both ends and can’t turn is called “fixed” or “castrated.” Overhanging means that a basic beam goes past its support on one end.

How many types of beams are there in structure?

Different buildings use different kinds of beams. Different types of construction beams are made for different types of supports, materials, cross-sections, shapes, and other things.

Why is beam used?

Beams are important structural parts that move weight from the slab to the columns. This means putting in transfer beams to move the load from one load-bearing wall to another. Most of the time, they are horizontal members. The purpose of a beam is to hold up walls and keep a concrete slab from getting too heavy.

What is beam strength?

You can compare the strength of two beams made of the same material by looking at their section modulus values. As the section modulus goes up, the beam gets stronger; the beam’s strength is proportional to the section modulus. The cross-section’s size, shape, and material all affect how strong the beam is.

How many types of beam and name them?

Cantilever beams, simply supported beams, overhanging beams, fixed beams, and continuous beams are all different kinds of beams.