Concrete Compressive Strength -Cube Test [PDF], Procedure, and Results

Concrete Compressive Strength -Cube Test [PDF], Procedure, and Results

The compressive Strength of the concrete cube test provides information on all concrete properties. This single test determines whether or not the concreting was done correctly. Concrete compressive Strength varies from 15 MPa (2200 psi) in general construction to 30 MPa (4400 psi) or higher in commercial and industrial structures.

Many factors influence concrete compressive Strength, including water-cement ratio, cement strength, substantial material quality, quality control during the manufacturing, and so on.

Compressive Strength is measured using a cube or a cylinder. A concrete cylinder or cube is recommended as the standard specimen for the test by various common codes. ASTM C39/C39M is a Standard Test Method published by the American Society for Testing Materials.

Definition of Compressive Strength

The ability of a material or structure to carry loads on its surface without cracking or deflection is called compressive Strength. When a material is compressed, its size decreases, whereas when it is tensioned, its size increases.

The formula for Compressive Strength

The compressive strength formula for any material is the load applied at the point of failure to the cross-section area of the face on which the cargo was used.

Compressive Strength = Load / Cross-sectional Area

Concrete Cube Compressive Strength Testing Procedur

Depending on the size of the aggregate, cubes of 15cm X 15cm X 15cm or 10cm X 10cm x 10cm are used for the cube test. Cubical molds 15cm x 15cm x 15cm are commonly used for most works.

This concrete is poured into the mold and adequately tempered to ensure that there are no voids. Molds are removed after 24 hours, and test specimens are immersed in water for curing. These specimens’ top surfaces should be even and smooth. This is accomplished by applying cement paste to the entire model surface and spreading it evenly.

After seven or 28 days of curing, these specimens are tested by compression testing machines. Load should be gradually applied at a rate of 140 kg/cm2 per minute until the model fails. The compressive Strength of concrete is calculated by dividing the load at failure by the area of the specimen.

The procedure for testing the compressive strength of concrete cubes is as follows.

Concrete Cube Testing Equipment

Compression testing apparatus

Concrete Cube Specimen Preparation

The proportions and materials used to create these test specimens are the same as those used in the field.

Specimen

Six cubes of 15 cm mix M15 or higher

Read More

-

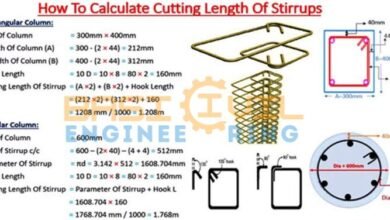

How to Calculate Cutting Length of Stirrups in columns

-

Concrete Compressive Strength -Cube Test [PDF], Procedure, and Results

-

Top 30 Questions and Answers for Interviews About Surveying

-

What’s the Contour Mapping?

-

Responsibilities of a Land Surveyor

-

Differents Types of Beams in Construction

-

Construction projects using concrete: Materials, Types, and Applications

-

16 Different Types Of Heavy Machinery Used In The Constructions

-

How to the Plan for Cold Weather Masonry Construction?

-

TYPES OF BUILDING FOUNDATIONS, SELECTION CRITERIA, AND BASIC REQUIREMENTS

-

How to plan the budget for home renovation

Concrete Mixing for Cube Test

Hand-mix the concrete or use a laboratory batch mixer.

Mixing by Hand

- On a watertight non-absorbent platform, thoroughly blend the cement and fine aggregate until the mixture is uniform in color.

- Mix in the coarse aggregate with the cement and fine aggregate until it is evenly distributed throughout the batch.

- Mix in the water until the concrete appears homogeneous and consistent.

Cube Sampling for Testing

- Clean and oil the mounds.

- Fill the molds with concrete in layers about 5 cm thick.

- Using a tamping rod, compact each layer with at least 35 strokes per layer (steel bar 16mm diameter and 60cm long, bullet-pointed at the lower end).

- With a trowel, level and smooth the top surface.

The Curing of Cubes

The test specimens are stored in moist air for 24 hours, after which they are marked, removed from the molds, and kept submerged in clear freshwater until the test.

Precautions for Examinations.

The curing water should be tested every seven days, and the temperature should be 27+-2oC.

Concrete Cube Test Procedure

- After the specified curing time, remove the specimen from the water and remove any excess water from the surface.

- Take the specimen’s length to the nearest 0.2m.

- Clean the testing machine’s bearing surface.

- Place the specimen in the machine so the load is applied to opposite sides of the cube cast.

- Align the specimen in the center of the machine’s base plate.

- Gently rotate the movable portion by hand until it touches the specimen’s top surface.

- Gradually and continuously apply the load at a rate of 140 kg/cm2/minute until the specimen fails.

- Take note of the maximum load and any unusual features of the type of failure.

Note:

At each age, at least three specimens should be tested. If the Strength of any model varies by more than 15% of its average Strength, the results should be rejected. The crushing Strength of concrete is determined by taking the average of three specimens.

Compressive Strength Calculations

The cube’s size is 15cmx15cmx15cm.

The specimen’s area (calculated from its mean size) is 225 cm2.

Compressive Strength (f ck) after seven days =

Maximum expected load =fck x area x f.s

The range to be chosen is………………..

A similar calculation should be performed for compressive Strength after 28 days.

Maximum applied load =………….tones =………….N

Compressive strength = (Load in N/Area in mm2)=……..N/mm2.

=……………………….N/mm2

Cube Test Reports

Identifying feature

The date of the test

The specimen’s age

Curing conditions, including specimen manufacture date

The appearance of fractured concrete faces, as well as the type of fracture if it is unusual

Concrete Cube Test Results

Concrete cube average compressive strength =………….N/mm2 (at 7 days)

Concrete cube average compressive Strength =…….. N/mm2 (at 28 days)

Concrete Compressive Strength at Different Ages

Concrete’s Strength increases with age. The table compares the Strength of concrete at various ages to the Strength at 28 days after casting.

Age Strength percent

One day 16%

Three days 40%

Seven days 65%

14 days 90%

28 days 99%

Why is a concrete compressive Strength test important?

The compressive Strength of the concrete cube test provides information on all concrete properties. This single test determines whether or not the concreting was done correctly.

What is the compressive strength of typical concrete?

Concrete compressive Strength varies from 15 MPa (2200 psi) in general construction to 30 MPa (4400 psi) or higher in commercial and industrial structures.

What is the compressive Strength after seven and fourteen days?

Concrete achieves approximately 65% of the target strength after seven days and about 90% after 14 days.

Which test is best for determining concrete Strength?

A concrete cube or cylinder test is commonly used to determine the strength of concrete after seven days, 14 days, or 28 days of casting.

What are the dimensions of the concrete cubes used for testing?

Depending on the size of the aggregate, cubes of 15cm X 15cm X 15cm or 10cm X 10cm x 10cm are used for the cube test. Cubical molds 15cm x 15cm x 15cm are commonly used for most works.

Which machine is used to test the strength of concrete?

The compressive Strength of concrete is tested using a compression testing machine.

What is the loading rate on the compression testing machine?

Load should be gradually applied at a rate of 140 kg/cm2 per minute until the specimen fails.

What ACI Code is used for the Concrete Strength Test?

ASTM C39/C39M is a Standard Test Method for the Compressive Strength of Cylindrical Concrete Specimens developed by the American Society for Testing Materials.