What is the Bricks & Important Tests on Brick

What is Bricks & Important Tests on Brick

What is a brick and what the required important tests on brick?

Bricks are a common building material used to the construct walls, foundations, chimneys, & other load bearing structures. They are made of clay or other earthen materials. Bricks are a common material for construction projects because of their strength, resilience, and fire resistance. Numerous tests are carried out to establish the properties and applicability of bricks to guarantee that they meet the necessary quality standards.

Tests on brick

Compressive Strength Test: This test determines the maximum load a brick can support before breaking. A brick sample is loaded using a device known as a compression testing machine until it breaks. A brick’s compressive strength is measured in the pounds per square inch (psi). A high-quality brick needs to be at least 5000 psi in compressive strength.

Absorption Test: This test gauges a brick’s porosity by the measuring how much water its can absorb. The brick is submerged in water for a predetermined amount of time, and the weight increase of the brick is then determined. A high-quality brick should absorb little energy, typically less than 15%.

Read More

-

How to Prepare Bar Bending Schedule of Slab with Example: A Comprehensive Guide

-

How to Find the Cutting Length of Bent Up Bar in Slab Reinforcement

-

Bar Bending Schedule Formulas: How to Calculate Reinforcement Bar

Efflorescence Test: This test determines whether a powdery white deposit, which can affect a brick’s appearance and durability, will likely form on its surface. The brick is placed in a moist environment, and the formation of efflorescence is observed. An excellent brick shouldn’t have efflorescence.

Hardness Test: This test evaluates the brick’s resistance to abrasion and surface wear. A brick is subjected to a predetermined load for the test, and the resulting indentation depth is measured. High hardness, typically greater than eight on the Mohs scale, is required for a superior brick.

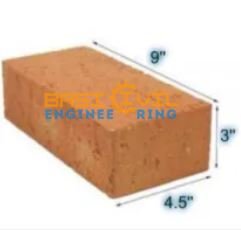

Shape and Size Test:This test demonstrates that the brick complies with the required sizes and shapes. A sample of bricks is measured for the test’s length, width, height, and corners. A high-quality brick should be consistent in size and shape.

Soundness Test:By measuring the brick’s resistance to freeze-thaw cycles, this test can help determine its durability when the weather changes. The brick is submerged in water for the test, which involves repeatedly freezing and thawing it. A high-quality brick shouldn’t show any indications of damage or cracking.

Strength Test:This test evaluates the brick’s overall durability and capacity to withstand different kinds of loads. The brick is subjected to a predetermined load for the test, and the resulting deformation is measured. A top-notch brick should be strong, usually more than 10,000 psi.

In conclusion, bricks are used extensively in construction and put through several tests to ensure they uphold the necessary quality standards. These brick tests offer crucial details about the bricks’ characteristics and help determine whether they are appropriate for a given application.