Curing of the Concrete | Curing time And Duration | What is Curing methods

Curing of the Concrete | Curing time And Duration | What is the Curing methods.

Concrete is a composite material made of the right amounts of cement, sand, and water. The aggregate is held together by the way the chemicals in the cement react with the water. Fresh concrete will be soft, so you can shape it into any shape you want and pack it down to make a solid mass.

Concrete should be put in place before it stops being able to be moved. The time when concrete stopped being soft and became hard all the way through is called its final setting time.

Curing of the concrete

Curing is a very important part of how concrete gets stronger and lasts longer. After adding water to the concrete mix (Cement, Sand, and Aggregate), hydration happens, which helps the concrete harden. Concrete doesn’t harden all at once; it takes longer, which means that more water is needed for the hydration process. So, the concrete stayed wet until the process of hydration was done. This is called letting concrete cure.

or

During the curing process, the concrete is kept moist so that it doesn’t lose water because of the temperature of the air and the hydration reaction.

or

Curing is the process of controlling how fast and how much concrete loses water during the hydration of cement.

Purpose of the Curing of Concrete

Curing concrete is done by letting water run off the surface of the concrete. Concrete can’t be cured with water that is cooler than 50C. As the hydration reaction in concrete gives off heat and keeps the concrete warm, using water with a temperature below 50°C may cause the concrete to crack and fail. When you alternately dry and wet the surface of concrete, the volume of the concrete changes, which can lead to cracks.

Procedure for curing of concrete

The concrete hardens when water runs off its surface. Water that is cooler than 50C can’t be used to cure concrete. As the hydration reaction in concrete releases heat and keeps the concrete warm, using water with a temperature of less than 50C may cause the concrete to crack and fail. When the surface of concrete is alternately dry and wet, the volume of the concrete changes, which can lead to cracks.

What is the curing period of the concrete?

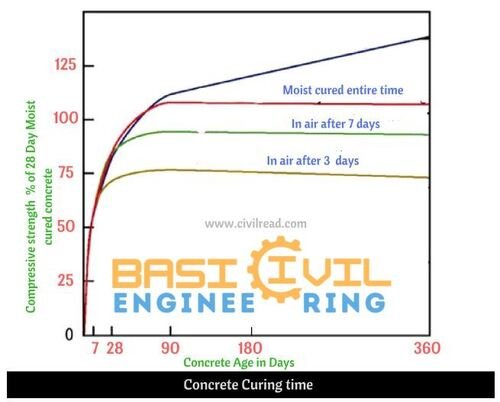

To get the most strength out of concrete, it needs to cure for at least 28 days.

Check out the graph below to get a better idea.

The above graph shows that concrete reached 50% of its designed strength after 3–7 days of curing. In 14 days, 75% of the compressive strength was reached. In 28 days, concrete is 90% as strong as it was meant to be. So it’s clear that as time went on, the concrete got stronger.

Read More

-

How to Find the Cutting Length of Bent Up Bar in Slab Reinforcement

-

Bar Bending Schedule Formulas: How to Calculate Reinforcement Bar

-

What is the Bricks & Important Tests on Brick

-

How to Prepare Bar Bending Schedule of Slab with Example: A Comprehensive Guide

-

Top 30 Questions and Answers for Interviews About Surveying

-

What’s the Contour Mapping?

-

Responsibilities of a Land Surveyor

-

Five Different Types of The Chains In the Civil Engineering

-

What is Land Surveying and its Types

-

Understanding, Components, Benefits, and Limitations of Dumpy Level Surveying

Minimum curing time for the cement concrete:-

The early strength of concrete is the most important, and it is what determines how strong it will be in the end. We should do proper curing by taking into account the weather, the type of structural members, and the temperature of the air. As was already said, keeping the right temperature is also very important for concrete. It shouldn’t be colder than 50C. At least 28 days pass while the concrete stays wet. Because people don’t have as much time as they used to, modern techniques can cure the wound in 14–20 days. Still, you should always keep concrete damp for at least 14 days.

IS 456–2000 says that ordinary Portland cement should cure for at least 7 days, and mineral admixtures or blended cement should cure for at least 10 days. If it’s hot and dry, the curing time for OPC shouldn’t be less than 10 days, and it should be 14 days for concrete made with a mix of cement and minerals.

How long it takes for concrete to harden depends on the following:

- Specified Strength of the Concrete

- Grate of the Concrete

- Atmospheric temperature:

Due to the chemical reaction between cement & water in the concrete releases heat which requires water to the complete hydration. In summer 50% of water is evaporated. So, More amount of the water needed during sunny days. - Size & Shape of Concrete member

Concrete Curing Methods:-

Here are the most important and widely used techniques from all over the world.

1. Ponding

This was used to make floor slabs. The concrete surface is broken up into small ponds, which are filled with water for 14 days straight.

2. Wet coverings

This method is used for columns, footings, and the bottom surface of slabs, where water cannot pool. To cover the concrete, you need something that won’t let water through, like gunny bags or hessian. Spraying water on these membranes will keep the concrete moist.

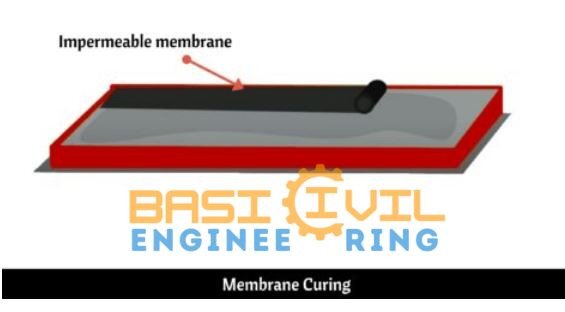

3. Membrane Curing of the Concrete:

When the air temperature is high, it’s not a good idea to make a pond. Because of the high heat, water evaporates. Membrane curing is used to stop concrete from losing water due to the temperature of the air.

Membrane curing helps seal by forming an impermeable layer on the surface of the concrete that eventually stops water from evaporating. Most of the time, this step is done by brushing or spraying the curing compound on the surface of the concrete.

To get the Membrane to cure, you can use different curing compounds. Below are four of the most important and widely used ones.

Synthetic resin curing compound

Synthetic resin is a chemical that forms an impermeable membrane on the surface of concrete to stop the concrete from losing water through evaporation.

Spraying hot water on the concrete surface is an easy way to get rid of the synthetic resin membrane so that more plastering can be done. So, it can be used in places where the concrete will be treated later.

Acrylic curing compound

Acrylic Curing compound is a polymer-based curing compound obtained from the polymers of Acrylic acid.

The best thing about Acrylic-based curing compound is that you don’t have to take it off before you plaster. Acrylic helps to achieve excellent adhesion to plastering.

Wax Curing compound

Wax hardens in the same way that synthetic resin does. Wax shouldn’t be used on surfaces that will be painted or tiled because it makes it harder for the surface to stick to the paint or tile.

Chlorinated rubber curing compound:

When laid on top of concrete, chlorinated rubber makes a thick membrane. Using a curing compound made of chlorinated rubber seals the concrete so well that there are no tiny holes left. But chlorinated rubber isn’t very old, and it can’t last for very long.

Steam curing of concrete

At a Precast concrete plant, where concrete parts are made in large quantities, this method is used. Steam has heat and moisture in it, and it is sprayed on the surface of the concrete to keep the concrete moist and to raise the temperature of the concrete, which speeds up the hardening process.

Curing of Concrete by the infrared radiation

This method is adopted in cold climatic regions. In this procedure, the infrared radiation is applied to the concrete, increasing the initial temperature, which increases the strength of concrete. This is the most effective method than steam curing, as raising the initial temperature in concrete does not decrease the ultimate strength of concrete. This technique is adopted for the hollow concrete members where the heaters are placed in concrete members which emit the temperature of 900

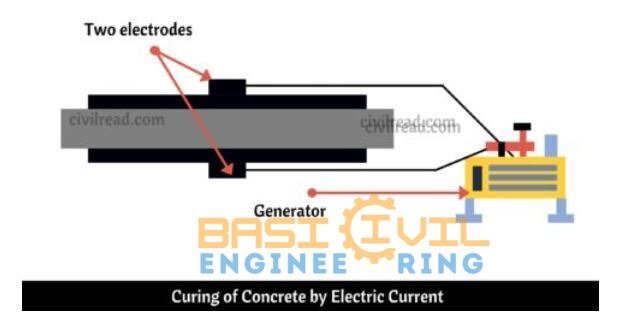

Curing of the concrete by an Electric Current

In this method, alternating current is used to cure the concrete. Two plates, one at the top and one at the bottom of the concrete surface, act as electrodes, and the alternating current is then sent to them. The potential difference between these electrodes is kept at 30V or 60V. With this method, you can get the same amount of curing in three days as you would in 28 days.